Hi, my name is Kristian, I’m 23 years old and my mission is to make Pellet 3D Printing globally less expensive and more accessible…

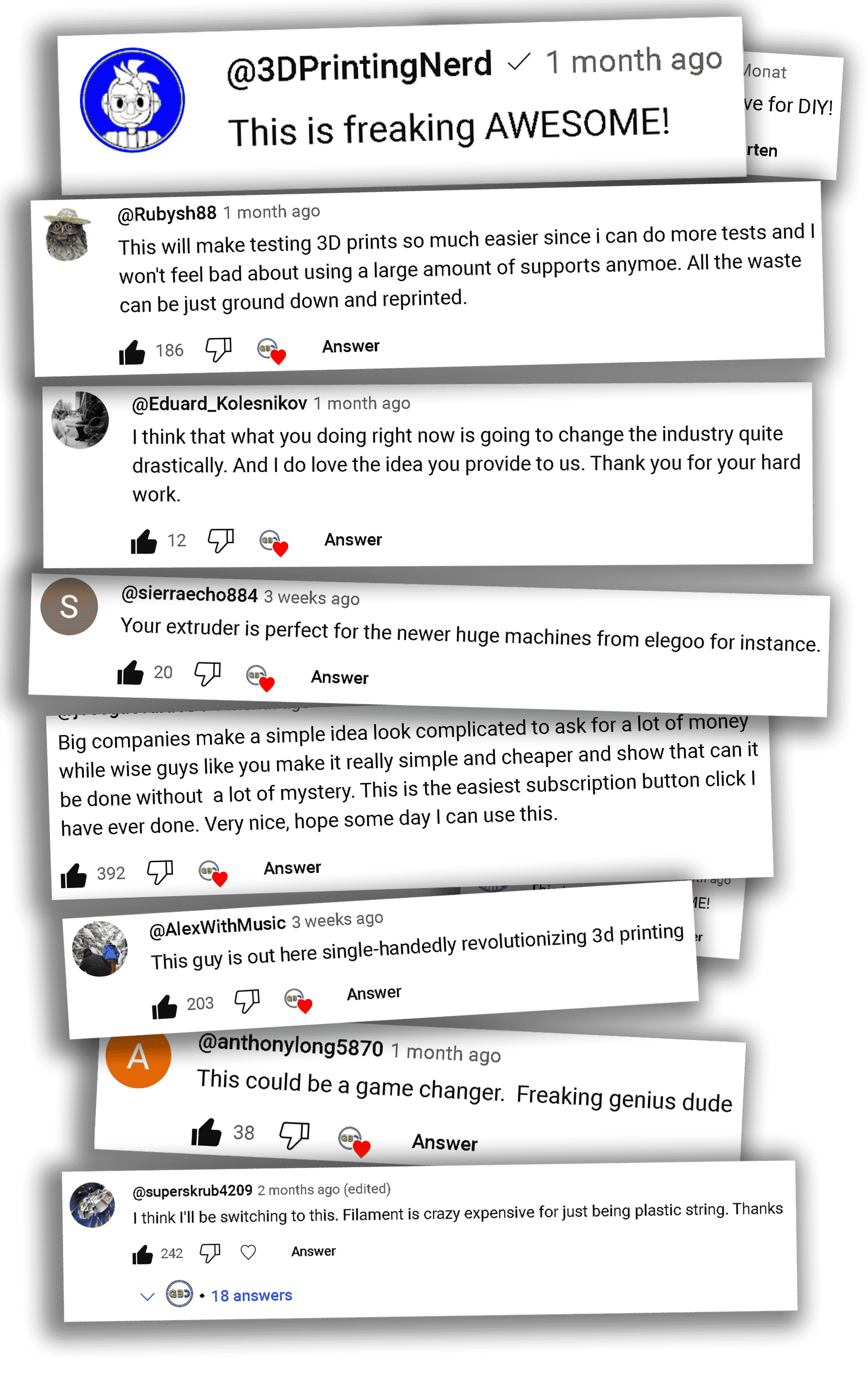

Back in the year 2022 I was very frustrated with the cost of 3D Printing and especially the waste it produces. At that time, I knew that 3D printing directly with Plastic Pellets & Shredded waste is possible.

But there were no low cost options, and it also seemed like as if the 3D printing industry doesn’t have much interest in developing this technology, despite its great potential.

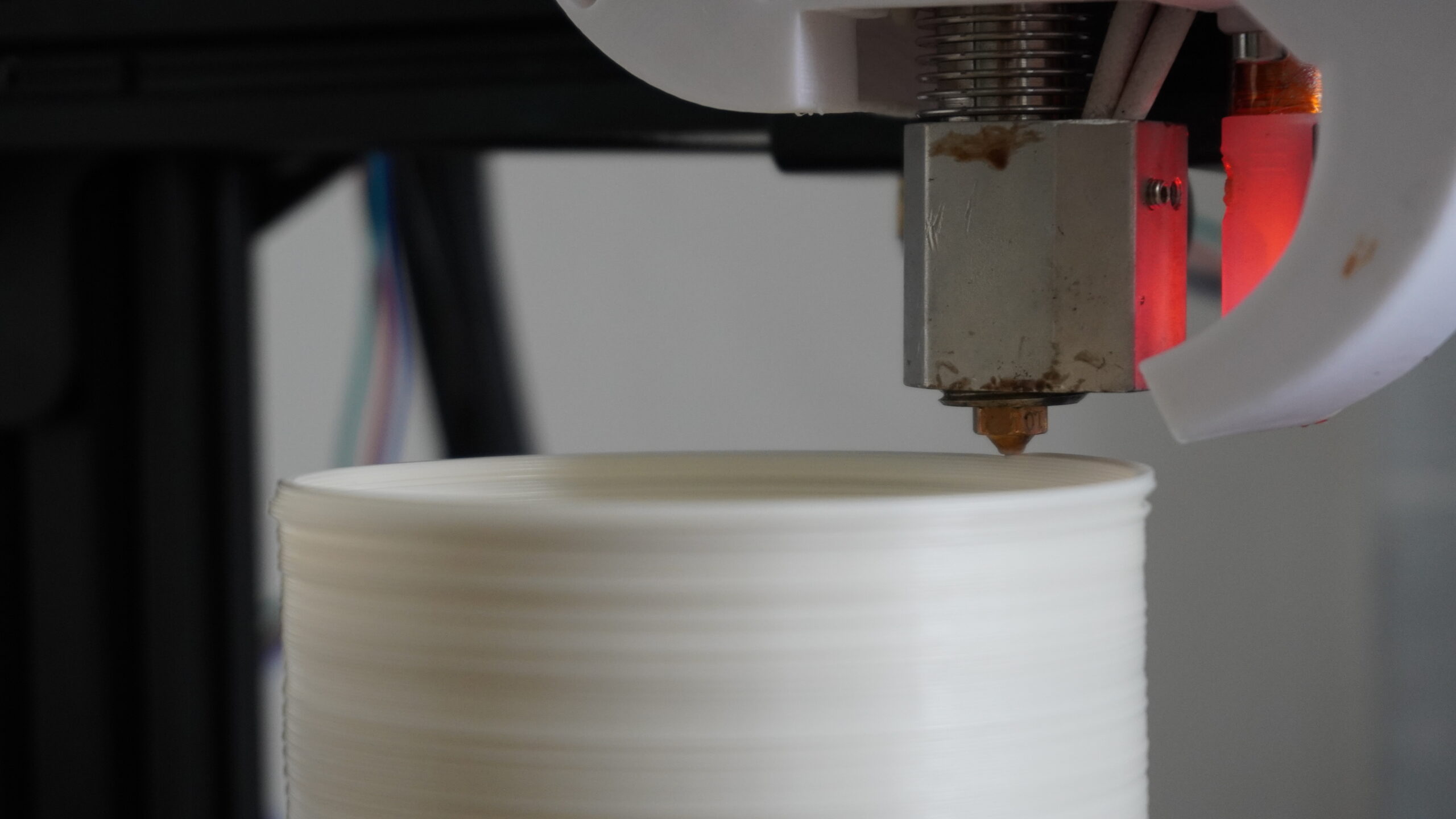

This frustrated me even more, so I decided to develop my own Pellet Extruder without having any knowledge about engineering at that time…

For more than 2 years I struggled, worked extremely hard and spent most of my income on the development while living under poor conditions…

No matter how hard times were, I never gave up and this why Greenboy3D exists today…